Solventless Lamination Machine

The Solventless Lamination Machine is a reliable apparatus engineered for the lamination of various materials such as BOPP, OPP, NY, PVC, CPP, VMCPP, aluminum foil, and PET film. It incorporates a five-roller coating system that significantly enhances its operational capabilities and precision. The machine is equipped with durable shaft-less unwind and rewind units, and employs closed-loop tension control through a dancer roller, along with an extensive computer control system for all functions. Its exceptional lamination pressure control ensures the consistent production of high-quality finished products. The machine also comes with a one-year warranty and is designed for continuous operation, running 24 hours a day, seven days a week. Its user-friendly design facilitates ease of use, making it an economically advantageous option for industry newcomers.

Solventless Lamination Machine

Solventless Lamination Machine

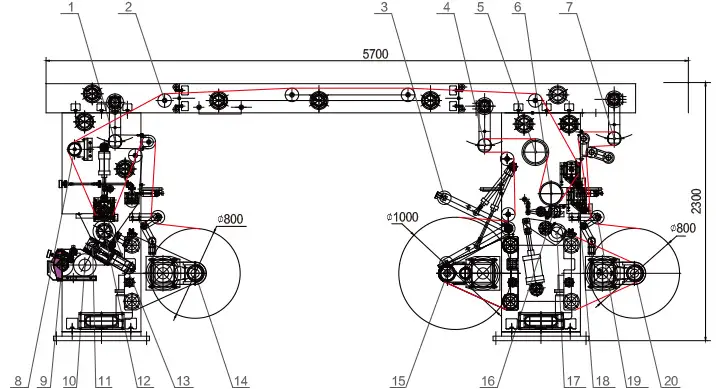

| 1. Tension Swimming Roller 2. Feeding Guide Roller 3. Rewinding Pressure Roller 4. Tension Swimming Roller 5. Cooling Roller 6. Laminating Roller 7. Tension Swimming Roller |

8. Tension Sense Roller 9. Doctor Blade Roller 10. Metering Roller 11. Gluing Roller 12. Coating Roller 13. Coating Pressure Roller 14. The First Unwinding |

15. The Rewinding 16.Laminating Pressure Roller 17. Laminating Back Pressure Roller 18. Adjustable Guide Roller 19. Moving Guide Roller 20. The Second Unwinding |

Technical Parameters:

| Item | BGFH-W |

| Max. Laminating Speed | 450 m/min |

| Max. Laminating Width | 1050/1250/1350mm |

| First Dia.of Unwinding | Max.Φ800mm |

| Second Dia.of Unwinding | Max.Φ800mm |

| Glue Spread | 1.0-3.0g/m |

| Laminated Film Type | BOPP, OPP, NY, PVC, CPP,Aluminum foil etc. |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

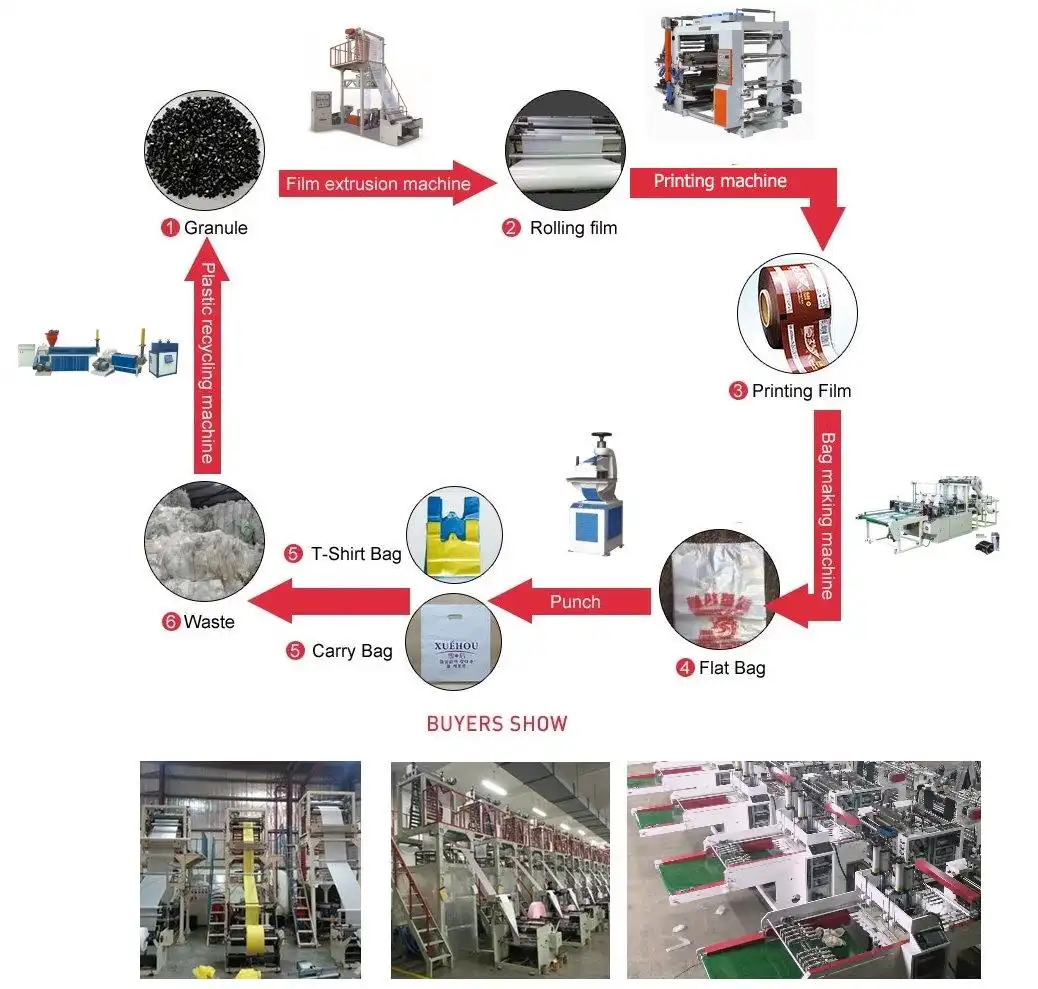

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;