slitting machine suit to slit big roll plastic film into small roll plastic film,suit to slit plastic film,paper roll,aluminum foil,stretch film.

BOPP Film Slitting Machine

A slitter machine is engineered to cut and rewind various roll materials, including BOPP, PET, CPP, CPE, PVC, aluminum foil, and paper. It is adept at accurately trimming, separating, and slicing materials to meet specific production needs. This machine incorporates edge position control and an automatic tension controller to optimize its performance, particularly in the context of a BOPP film slitting machine.

The slitter machine is engineered to process LDPE, HDPE, LLDPE, BOPP, PP, PET films, and paper, accommodating widths from 100mm to 1300mm.

It incorporates an inverter-controlled speed system to promote energy efficiency and cost savings.

With edge position control and an automatic tension controller, this machine provides accurate slitting performance.

Constructed from 38CrMoAl screw material, it ensures durability for long-term operation. Backed by a one-year warranty, it is capable of continuous 24/7 functionality.

Its user-centric design makes it suitable for novices, with adaptable power options to meet regional specifications (e.g., USA 480V 60Hz, Mexico 440V/220V 60Hz).

Post-sale services include on-site installation and training conducted by skilled engineers. Custom machinery and OEM designs are also accepted.

| Type | LFQ-700A | LFQ-1100A | LFQ-1300A |

| Max.Width of Mother Roll | 700mm | 1100mm | 1300mm |

| MAX.Diameter of Mother Roll | Φ600mm | Φ600mm | Φ600mm |

| Width of Final Roll | 30-600mm | 30-600mm | 30-600mm |

| Material | BOPP,OPP,CPP,PET,LDPE,HDPE,Paper | ||

| Slitting and Rewinging Speed | 5-160m/min | 5-160m/min | 5-160m/min |

| Tolerance of EPC | <±0.5mm | <±0.5mm | <±0.5mm |

| Total Power | 2.7kw | 3.5kw | 3.5kw |

| Machine Weight | 1200kg | 1500kg | 1800kg |

| Machine size | 2000×1110×1400mm | 2400×1110×1400mm | 2600×1110×1400mm |

| Power Voltage | 220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz…) | ||

| Material Core Diamater | 58mm,76mm | ||

| Machine Working Time | 24 hours * 7 days | ||

| Warranty | 1 year | ||

| Technical Assistance | Engineers available to service machinery overseas | ||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

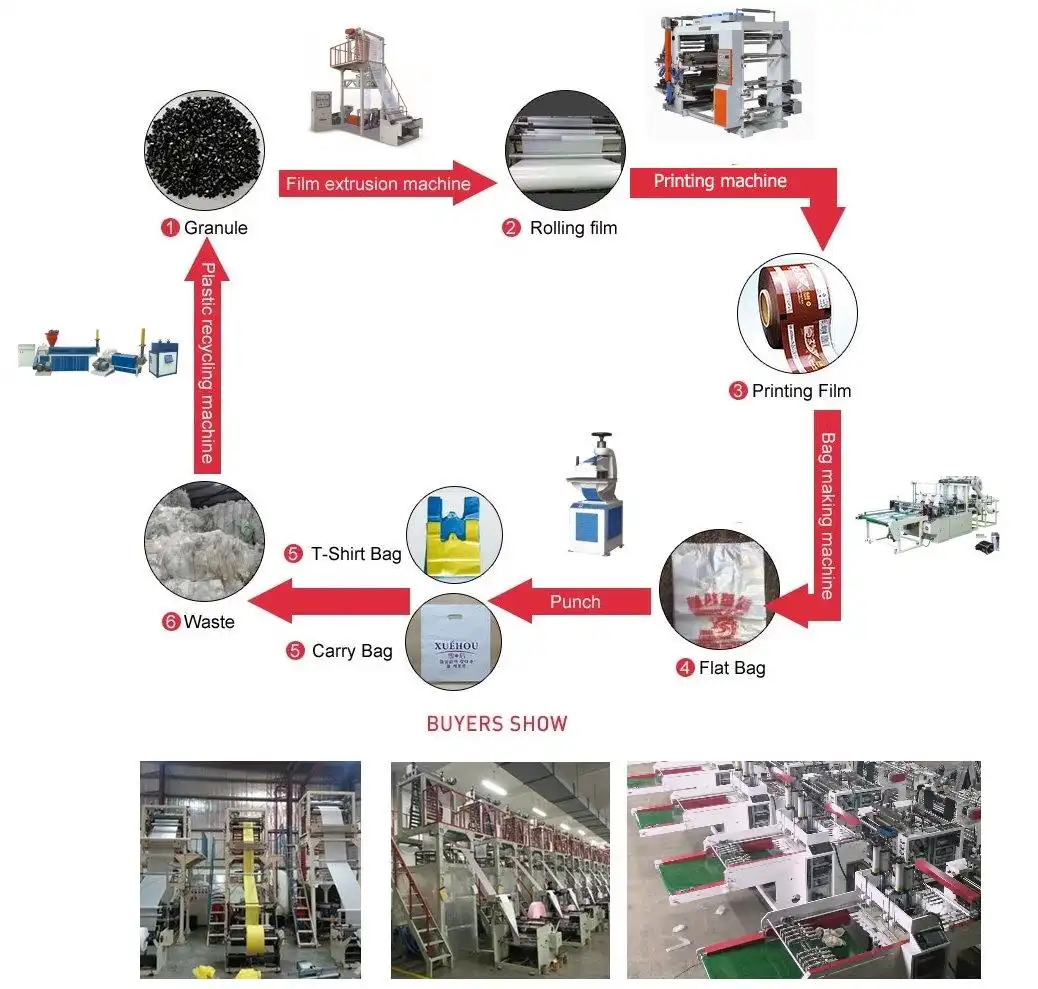

If you only buy one machine,we will pack machine with wooden pack,and loading container withLess Than Container Load(LCL). If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load). Our Main parts cooperator as following brand,but standard parts all made from China. How To Find Polyethelene For Blown Film Extrusion. Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).Shipment

shipment of plastic bag machine

instalment service

install machines in customer factory

Machine parts supplier

Material supplier

Extrusion Film Extrusion use Polyethelene,such as

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;