Plastic Grinding Milling Granulator

Integrating a plastic grinding milling granulator into your system enhances efficiency.

Utilizing a plastic grinding milling granulator enhances material recovery and reduces waste.

Investigate the benefits of integrating a Plastic Grinding Milling Granulator into your manufacturing workflow.

With a plastic grinding milling granulator, waste is processed more effectively.

The implementation of a Plastic Grinding Milling Granulator can greatly improve the effectiveness of your recycling efforts.

Investing in a plastic grinding milling granulator allows for significant cost savings in the long run.

Designed to effectively reduce plastic waste, the Plastic Grinding Milling Granulator is an essential tool for any organization committed to sustainability.

This technology, specifically the plastic grinding milling granulator, supports eco-friendly initiatives.

This machinery utilizes advanced design techniques and incorporates rapid grinding, continuous agitation, milling, fractioning, and a heating process with multiple knives, including a plastic grinding milling granulator for optimal performance. The plastic grinding milling granulator adeptly transforms waste materials such as plastic films, filaments, ribbons, soft plastic pipes, foams, and other degradable substances into granules that are ideal for recycling and reproduction, making it the most sophisticated solution available for plastic recycling. The Plastic Grinding Milling Granulator guarantees outstanding processing efficiency.

Main Technical Variables:

| 1 | Capacity of Barrel | 150L | 100L |

|

|

| 2 | Output Capacity | 60-80kg/h | 30-60kg/h | ||

| 3 | Main Motor Power | 18kw | 15kw | ||

| 4 | Water Adding Device | 125w | 125w | ||

| 5 | Heating Power | 1.5kw | 1.5kw | ||

| 6 | Rotary Speed of Main Shaft | 660r/min | 660r/min | ||

| 7 | Overall Dimensions | 1500×700×1400mm | 1300×600×1300 mm |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

With the introduction of a plastic grinding milling granulator, businesses can achieve higher standards in waste management.

Plastic Grinding Milling Granulator

Explore how the plastic grinding milling granulator can revolutionize your recycling process.

A plastic grinding milling granulator is a game-changer in the recycling industry, providing unmatched durability and efficiency.

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

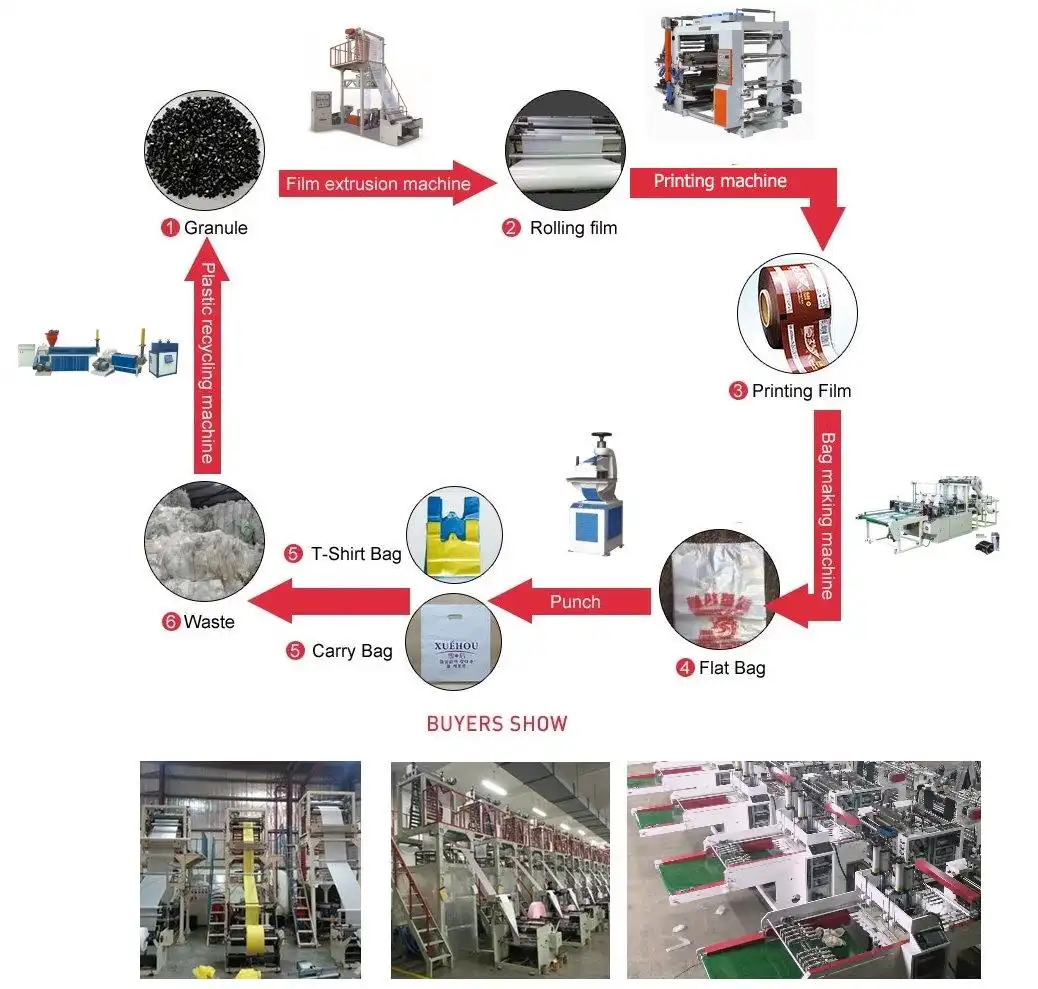

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;